Morooka MST600VD Rubber Tracks

Prowler offers a premium aftermarket rubber track for the Morooka MST600VD carrier dumper. The track size is 500x90x78 and weighs approximately 1046 lbs. The width of this track is 19.7 inches and it has 78 links. The Prowler cross-application tread design will provide exceptional efficency, performance, and service life for your carrier.

| Morooka MST600VD Rubber Track Specs | |||||

|---|---|---|---|---|---|

| WEIGHT (lbs) | WIDTH (mm) | PITCH (mm) | LINKS | ||

| 1046 | 500 | 90 | 78 | ||

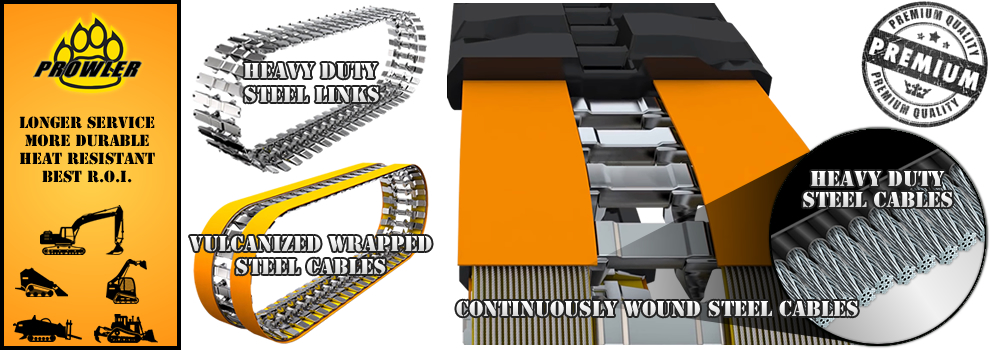

Premium Morooka MST600VD Rubber Track Features

- All natural rubber: Natural rubber provides elasticity and resilience, making it an essential component in rubber track manufacturing. It offers excellent tensile strength and tear resistance, contributing to the overall durability of the track.

- Continuously wrapped steel cords: Continuously wrapped steel cords provide excellent strength and durability to the rubber track. The steel cords reinforce the rubber, allowing the track to withstand heavy loads, rough terrain, and prolonged use without easily breaking or stretching.

- Synthetic compounds: Various synthetic rubbers, such as styrene-butadiene rubber (SBR), ethylene-propylene-diene monomer (EPDM), and polyurethane (PU), are often blended with natural rubber to enhance specific properties like abrasion resistance, weather resistance, and flexibility.

- Carbon black: Carbon black is added to rubber compounds to improve strength, abrasion resistance, heat resistance, and UV stability. It also helps enhance the track’s grip and traction on various surfaces.

- Vulcanized rubber: The inner band of steel cords are wrapped by a thick layer of vulcanized rubber that improves the track’s resistance to heat, pressure, and deformation. It also helps protect the cords from moisture.

- Antioxidants and antiozonants: These additives protect the rubber from degradation caused by exposure to oxygen and ozone, extending the service life of the rubber track.