Prowler Premium Rubber Tracks

Precision And Reslience In Every Track: Experience Prowler Quality

Since 1998, Prowler has been a trusted name in the construction equipment industry, specializing in premium aftermarket rubber tracks. Our product line is designed to meet the rigorous demands of modern construction and excavation projects, providing unmatched durability and performance.

Since 1998, Prowler has been a trusted name in the construction equipment industry, specializing in premium aftermarket rubber tracks. Our product line is designed to meet the rigorous demands of modern construction and excavation projects, providing unmatched durability and performance.

Our extensive range of rubber tracks caters to a variety of equipment, including excavators, track loaders, mini dozers, trenchers, drillers, mini skid steers, and carrier dumpers. Each Prowler rubber track is engineered for superior performance, reduced vibration, and increased longevity, ensuring your machinery operates at peak efficiency on any job site.

At Prowler, we are committed to delivering exceptional value and convenience to our customers. That’s why we offer free shipping anywhere in the lower 48 states, ensuring you receive your tracks quickly and without added costs.

Choose Prowler for reliable, Premium Quality Rubber Tracks that keep your construction equipment running smoothly and efficiently. Join the many professionals who trust Prowler to provide the best aftermarket solutions for their machinery.

FREE SHIPPING NATIONWIDE

Premium Grade Rubber Tracks for Compact Construction Equipment can be purchased and shipped direct to you anywhere in the lower 48 States within 1 to 4 business days. We provide construction tracks for;

- Compact Tracks Loaders (CTL Machines)

- Multi-Terrain Loaders (MTL Machines)

- Mini Excavators

- Mini Skid Steer Loaders (Walk Behinds)

- Mini Bulldozers

- Carrier Dumpers

- Trenchers and Drillers

We have over 4000 makes and models that we supply aftermarket replacement rubber tracks for that meet OEM specifications, and exceed ISO-9001 quality guidelines for guaranteed fitment and high quality, long lasting design.

Do not waste your money paying more to a Dealer, when you can buy an equal or better quality track from a premium grade rubber track supplier like Prowler MFG.

Rubber Track Tread Designs For All Applications

Premium Grade Rubber Track Features And Benefits

Compact construction equipment requires rubber tracks that are manufactured to perform efficiently within a wide range of applications such as mud, dirt, clay, sand, gravel, asphalt, and snow. When considering factors like climate, the weight of your machine, the condition of your undercarriage parts, the experience and awareness of your operator, and the material you are handling, it becomes clear why you should opt for a premium-grade track over a standard-grade brand.

So what makes Prowler Premium Grade Tracks worth paying more for, and what components and materials are used to manufacture them? Here’s whats inside;

Premium grade tracks are composed of high concentrations of carbon black and less synthetics. This composition allows your machine to operate on surfaces at elevated temperatures, such as asphalt during the summer months, without the rubber wearing away as quickly while making “power turns” as an example. Premium tracks also typically have a higher durometer rating, reducing the chance of gouges or abrasions caused by traveling over sharp edged debris or asphalt.

Premium grade tracks are composed of high concentrations of carbon black and less synthetics. This composition allows your machine to operate on surfaces at elevated temperatures, such as asphalt during the summer months, without the rubber wearing away as quickly while making “power turns” as an example. Premium tracks also typically have a higher durometer rating, reducing the chance of gouges or abrasions caused by traveling over sharp edged debris or asphalt.

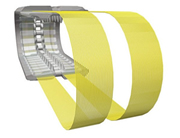

Heavy-duty steel links serve as a sturdy skeleton and engagement point for your drive sprocket. Because these steel-embedded links play multiple roles, they must be made of high-quality materials. Under high torque, your drive sprocket grabs and pulls these links, so they need to be strong enough to withstand these forces. Additionally, they create a “rolling path” for your bottom rollers to travel along. More-so, they must be capable of enduring sudden impacts with curbs, large rocks, or other unforseen hazards. Heavy-duty steel links are essential and are always found in premium-grade rubber track.

Heavy-duty steel links serve as a sturdy skeleton and engagement point for your drive sprocket. Because these steel-embedded links play multiple roles, they must be made of high-quality materials. Under high torque, your drive sprocket grabs and pulls these links, so they need to be strong enough to withstand these forces. Additionally, they create a “rolling path” for your bottom rollers to travel along. More-so, they must be capable of enduring sudden impacts with curbs, large rocks, or other unforseen hazards. Heavy-duty steel links are essential and are always found in premium-grade rubber track.

Heavy-duty steel cords that are continuously wound are essential components required to construct a premium-grade rubber track. This method of manufacturing our tracks reduces or eliminates the chance of cords splitting apart or snapping, unlike spliced or overlapped cables commonly used by standard-grade track suppliers. Additionally, a premium-grade track always wraps these steel cables in thick vulcanized rubber. This helps protect the cords from deep gouges caused by sharp objects or moisture that may reach the cables through channels created by these gouges.

Heavy-duty steel cords that are continuously wound are essential components required to construct a premium-grade rubber track. This method of manufacturing our tracks reduces or eliminates the chance of cords splitting apart or snapping, unlike spliced or overlapped cables commonly used by standard-grade track suppliers. Additionally, a premium-grade track always wraps these steel cables in thick vulcanized rubber. This helps protect the cords from deep gouges caused by sharp objects or moisture that may reach the cables through channels created by these gouges.

Even though premium grade rubber tracks cost more, they will always give you a longer service life, provide better protection from the elements, and lower operating cost. They are definitely worth paying a little more for as they are an excellent return on your investment.

Internal Components Of A Premium Grade Rubber Track

Continuously wound steel cords constitute a type of cable construction frequently employed in diverse engineering and industrial applications. Typically, these cables consist of multiple strands of high-strength steel wire twisted or braided together, yielding a flexible yet exceedingly durable cable system.