Premium Mini Excavator Rubber Track Design

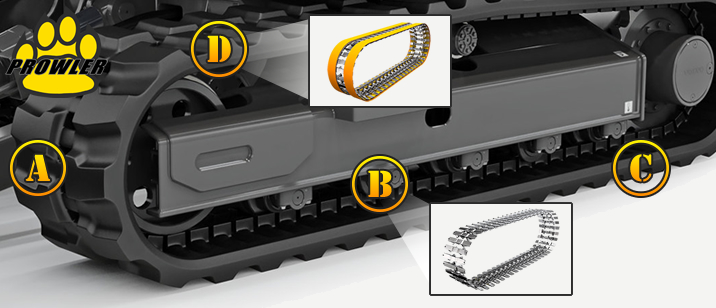

Prowler rubber track systems are rigorously tested before being put into service. Our Excavator Rubber Tracks are designed to OEM specifications for a perfect fit every time. To improve their dependability and durability, they undergo extensive research and design tests to ensure the compounds and materials used during production meet or exceed ISO quality standards. Here are just a few features you will find in every premium grade track we sell:

Why choosing the right rubber track system for your full size or mini excavator is a vital decision for both owners and operators;

Why choosing the right rubber track system for your full size or mini excavator is a vital decision for both owners and operators; Your return on investment begins with the materials and components used in the manufacturing of your new excavator rubber tracks, including modern molding and curing processes, and enforced quality control guidelines. The constant stress from torque generated by your machine, terrain hazards, and weather can quickly take a toll on your tracks. Inferior parts and materials also equal a shorter track life. It isn’t cost effective or productive to replace tracks every few hundred hours. You may pay a little more to get a superior quality rubber track, but the return on investment saves you money in the long run. Our tracks reduce downtime, provide a longer service life, and are backed by an 18 month/1500 hour warranty.

Your return on investment begins with the materials and components used in the manufacturing of your new excavator rubber tracks, including modern molding and curing processes, and enforced quality control guidelines. The constant stress from torque generated by your machine, terrain hazards, and weather can quickly take a toll on your tracks. Inferior parts and materials also equal a shorter track life. It isn’t cost effective or productive to replace tracks every few hundred hours. You may pay a little more to get a superior quality rubber track, but the return on investment saves you money in the long run. Our tracks reduce downtime, provide a longer service life, and are backed by an 18 month/1500 hour warranty.